DI Gottfried STEINER

SUCCESS is our SERVICE

Since the founding of IB STEINER in 1995, our customers select out of a comprehensive range of polymer engineering services. The focus lies on development and construction of polymer components, inventiveness for innovations, competence analysis, simulation and development of new technology processes as for example the EXJECTION® technology.

SUCCESS is our SERVICE

Since the founding of IB STEINER in 1995, our customers select out of a comprehensive range of polymer engineering services. The focus lies on development and construction of polymer components, inventiveness for innovations, competence analysis, simulation and development of new technology processes as for example the EXJECTION® technology.Competent, professional qualified and targeted to economic efficiency we elevate the state of the art and analyse the requirement. Thereafter we develop, test and evaluate the solution of the variants for your product. We also support our clients to introduce their innovation in the market.

Leading Competence in

Polymer Engineering

-

AIRBUS A380

For the aircraft and automotive industries the focus is laying on weight reduction at a max, high functionality combined with safety aspects and a short period of development time. Since the early days IB STEINER is a competent partner for development of high quality and functional components and interior parts in civil aircrafts, such as the world's largest window assembly, developed for the AIRBUS A380.

"Innovation instead of redesign" is one of the leading headlines in that forward-thinking business, and reflects also perfectly into other industries of the modern century. -

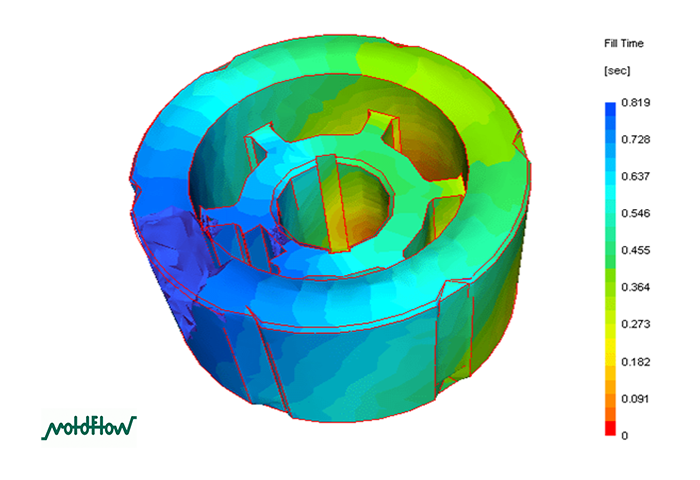

Use of Simulation Tools

Decades of experience in the use of virtual simulation tools and mechanical simulations, allow a fast implementation and a standardised support for development of single or multiple mould components and parts. Virtual redesign of products enables lightweight construction in combination with lower development and manufacturing costs. -

Material Competence

A comprehensive materials competence over the whole range of natural and synthetic polymers, combined with a long standing experience with high temperature thermoplastics and the application of material combinations/hybrid technologies such as wood + polymer, metal + polymer and ceramic + polymer is a benefit for our customers. -

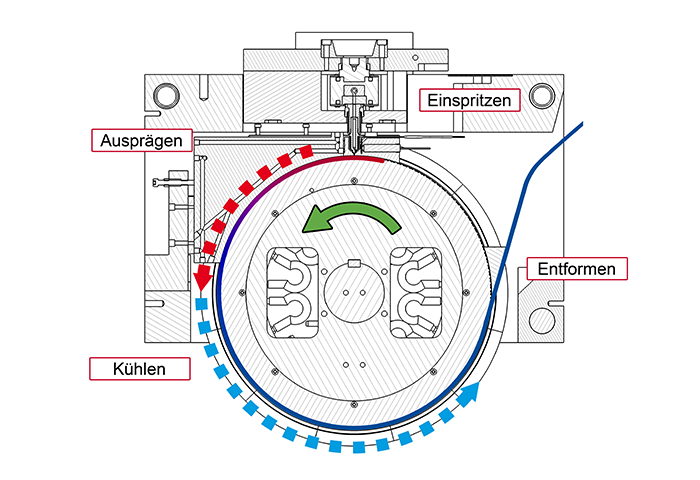

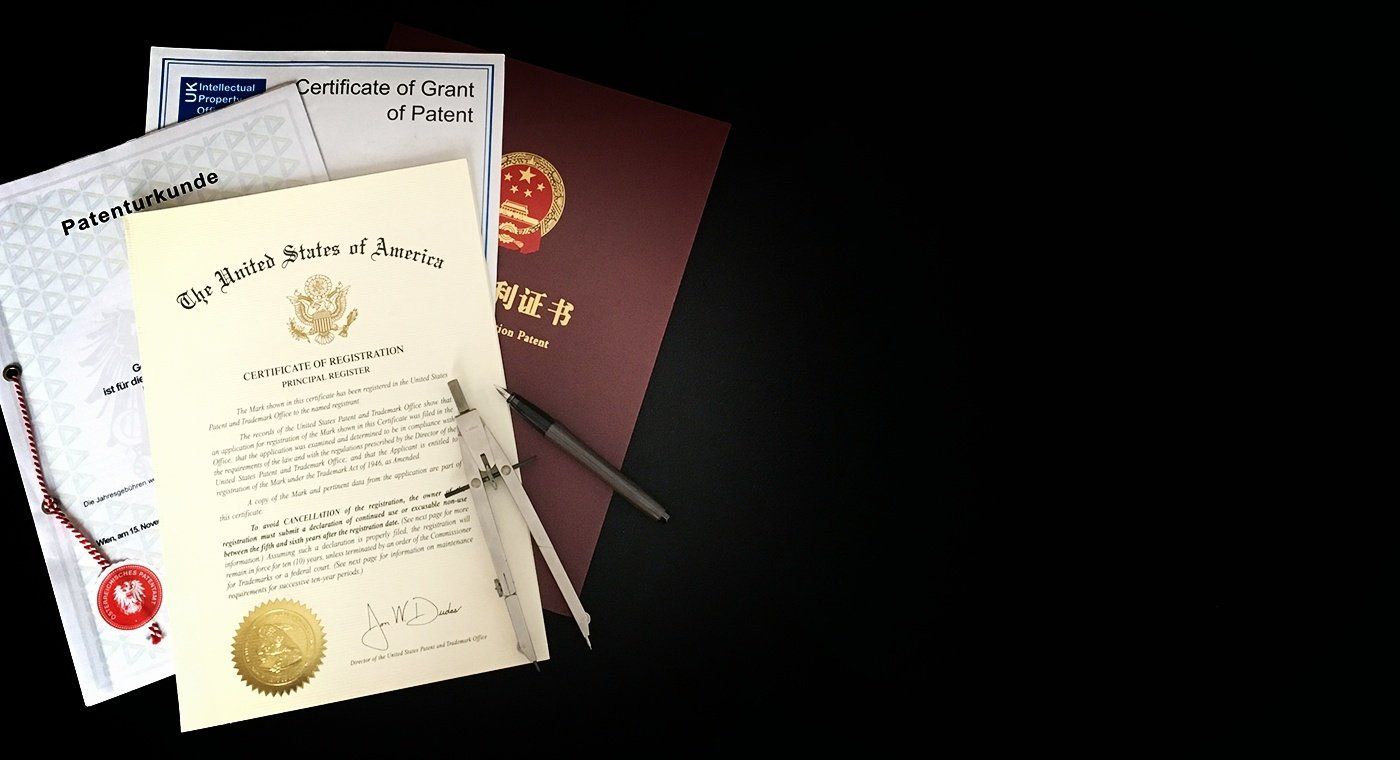

Technology | EXJECTION Endless

The EXJECTION technology is a special injection moulding process, developed by IB STEINER and applied for a patent. This innovative continuous moulding technology combines the advantages of extrusion and injection moulding. It is ideally suited to the production of long, thin-walled and structured parts with low clamping force. -

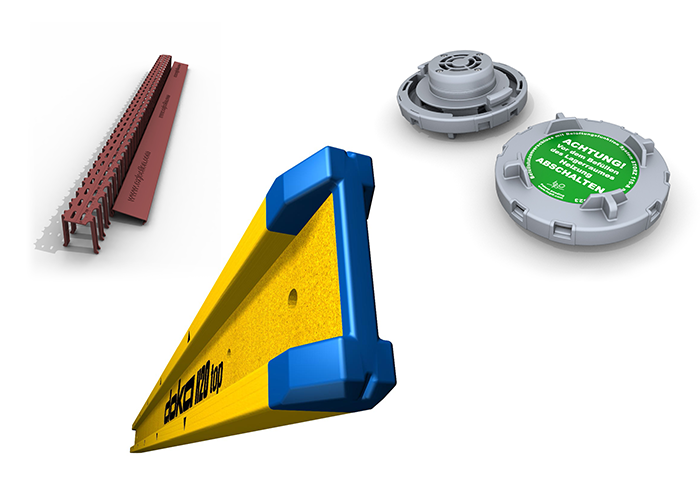

Innovative Product Development

Together with our clients we draft an individual project schedule, which is exclusively tailored to the needs of their needs. Based on economic criteria, we raise the state-of-the-art and analyse the requirements. Afterwards we verify and evaluate solution variants and develop products with unique selling proposition, as well in functional as in economic aspect. -

Research Laboratory

The research lab with technical center for injection molding technology of IB STEINER carries out investigations into the development of new technologies, which are the basis for a later series conversion. The process capability of new processes is also explored and improved, such as the use of intelligent materials, better known as smart materials. -

YOUR BENEFITS

Increased competitiveness by more functionality, a high product quality and a reduction of material and production costs for example. This is perfectly realized in several innovative products such as the valve of a portable fire extinguishers or a FILLING NOZZLE of a pellet chamber, but also in the WINDOW ASSY for the new AIRBUS generation. -

Trainings in Polymer Competence

In the course of projects we transfer our knowledge to customers. In several trainings, the employees receive project-related know-how about process sequences, simulations, shape concepts, component design, materials and technical/economic assessments, as well as specific expertise. Training is also possible independently of projects.

Wood in Automotive Industry

The combination of the traditional material of wood with high tech-plastic allows using the advantages of both materials which can be used effectively for weight saving and performance gains within innovative componant design.

Continuous Moulding

Through the use of modern technologies, such as EXJECTION, for production of innovative products, favourable functions, high product quality and more productivity can be achieved continuously.

INNOVATION instead of REDESIGN

We are investing up to 100 % of our company potential into R&D projects for further development of competence and to maintain the market advantages towards our faithful customers.

Tracking TRENDS ...

-

Services

Our customers can rely on extensive range of polymer competence, and the advantages of state-of-the-art development tools.

- Development of parts und products

- Feasibility studies

- Process simulations

- Injection moulding process developments

-

in all industry sectors ...

Around 280 customers of IB STEINER distribute themselves to almost all industry sectors and industries of the modern age.

- Automotive Industry

- Aviation

- Life Science

- Construction Industry

- Consumer Goods

-

... recommended by customers !

More than 2.000 successfull development projects are the basis for new and innovative solutions in all areas of polymer engineering. To talk about product success we kindly leave up to our customers.

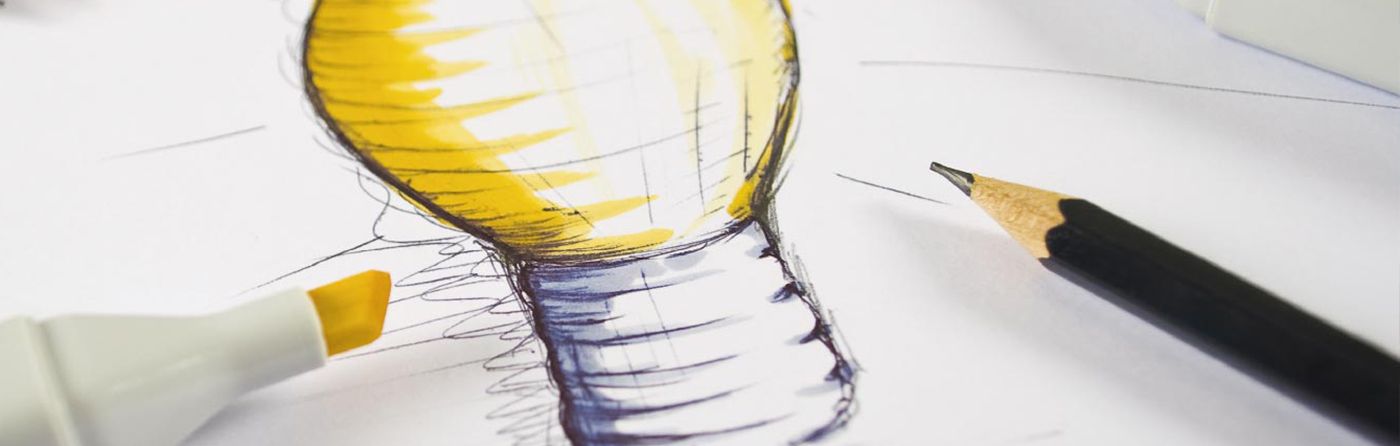

Interior for AIRBUS

Console for AUDI

Palcom P7 for PALFINGER

-

-

National Award 2009 CONSULTING

For the development of the EXJECTION Technology, IB STEINER has received the National Award Consulting 2009 by ACA in cooperation with the Austria Federal Ministry of Economy, Family and Youth. This innovative technology is an outstanding example for the international reputation of austrian engineering services and mould manufacturers.